4D Bioprinting and its Applications in Orthopaedics

Featured

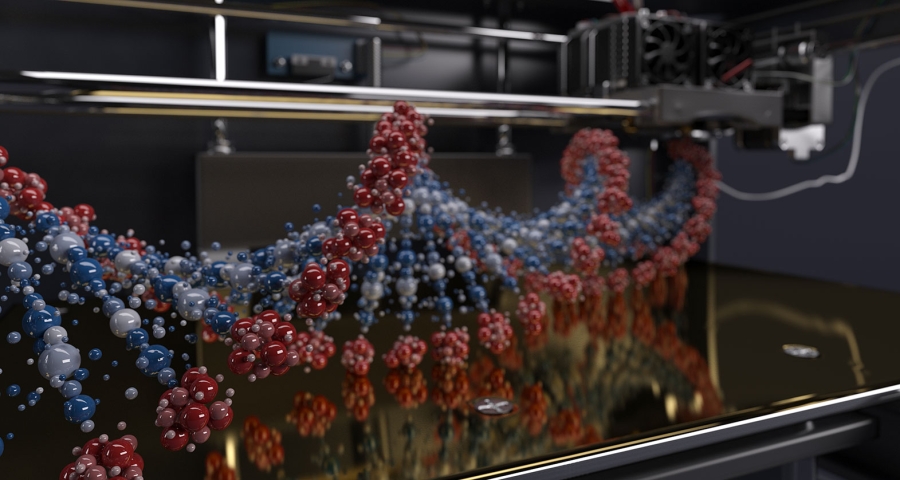

4D bioprinting represents an advanced evolution of 3D bioprinting, integrating the fourth dimension—time. This technology involves creating bioprinted structures that can change shape or function over time in response to specific stimuli, such as temperature, pH, or moisture. The ability to produce dynamic, adaptable structures opens new possibilities in tissue engineering and regenerative medicine.

Mechanism of 4D Bioprinting

4D bioprinting leverages materials known as smart biomaterials or stimuli-responsive materials. These materials can undergo a programmed transformation after printing due to intrinsic properties or external stimuli. The primary mechanisms include:

-

Shape-memory polymers: These materials can revert to a predefined shape when exposed to a specific trigger, like heat.

-

Hydrogels: Often used for their biocompatibility and ability to swell or shrink in response to environmental changes.

-

Self-assembling systems: Utilizing cellular or molecular interactions to form desired structures post-printing.

Applications in Orthopaedics

In orthopaedics, 4D bioprinting offers transformative potential in several key areas:

Traditional implants are static and may not adapt well to the changing conditions within the body. 4D bioprinting can create implants that adapt over time to better integrate with surrounding tissues, reducing the risk of rejection and improving long-term outcomes.

Scaffolds designed for bone and cartilage regeneration can benefit from 4D bioprinting by changing shape or releasing growth factors in a controlled manner, promoting better tissue integration and faster healing.

Prosthetics can be made to dynamically adjust to the user’s movements or changes in their physical condition, providing enhanced comfort and functionality.

4D bioprinting enables the creation of patient-specific models and treatment solutions that adapt over time, ensuring better alignment with individual healing processes and needs.

Current Research and Future Directions

Researchers are exploring various aspects of 4D bioprinting for orthopaedics:

-

Material Development: Identifying and synthesizing new smart biomaterials that are biocompatible and capable of precise transformations.

-

Biological Integration: Ensuring that 4D printed structures interact optimally with human cells and tissues.

-

Clinical Trials: Moving from laboratory research to clinical applications requires extensive testing and validation to ensure safety and efficacy.

Challenges and Considerations

While promising, 4D bioprinting in orthopaedics faces several challenges:

-

Material Limitations: The development of suitable materials that are both biocompatible and capable of precise, predictable transformations is complex.

-

Scalability: Moving from small-scale laboratory models to full-sized human implants presents significant technical hurdles.

-

Regulatory Approval: Ensuring that new 4D bioprinting techniques meet regulatory standards for medical devices and treatments.

Conclusion

4D bioprinting holds significant promise for revolutionizing orthopaedics by providing dynamic, adaptable solutions tailored to individual patient needs. As research progresses, this technology has the potential to improve outcomes in bone and tissue regeneration, implant integration, and personalized medicine.